3D Printing In Schools, Colleges And Businesses: Managing the Risks

Introduction:

Over recent years there has been an increase in the use of 3D printing in schools and colleges. Whilst this is an exciting and innovative new technology, there is now evidence that there are health and safety risks associated with the process of heating and extruding plastic filament to form 3D objects.

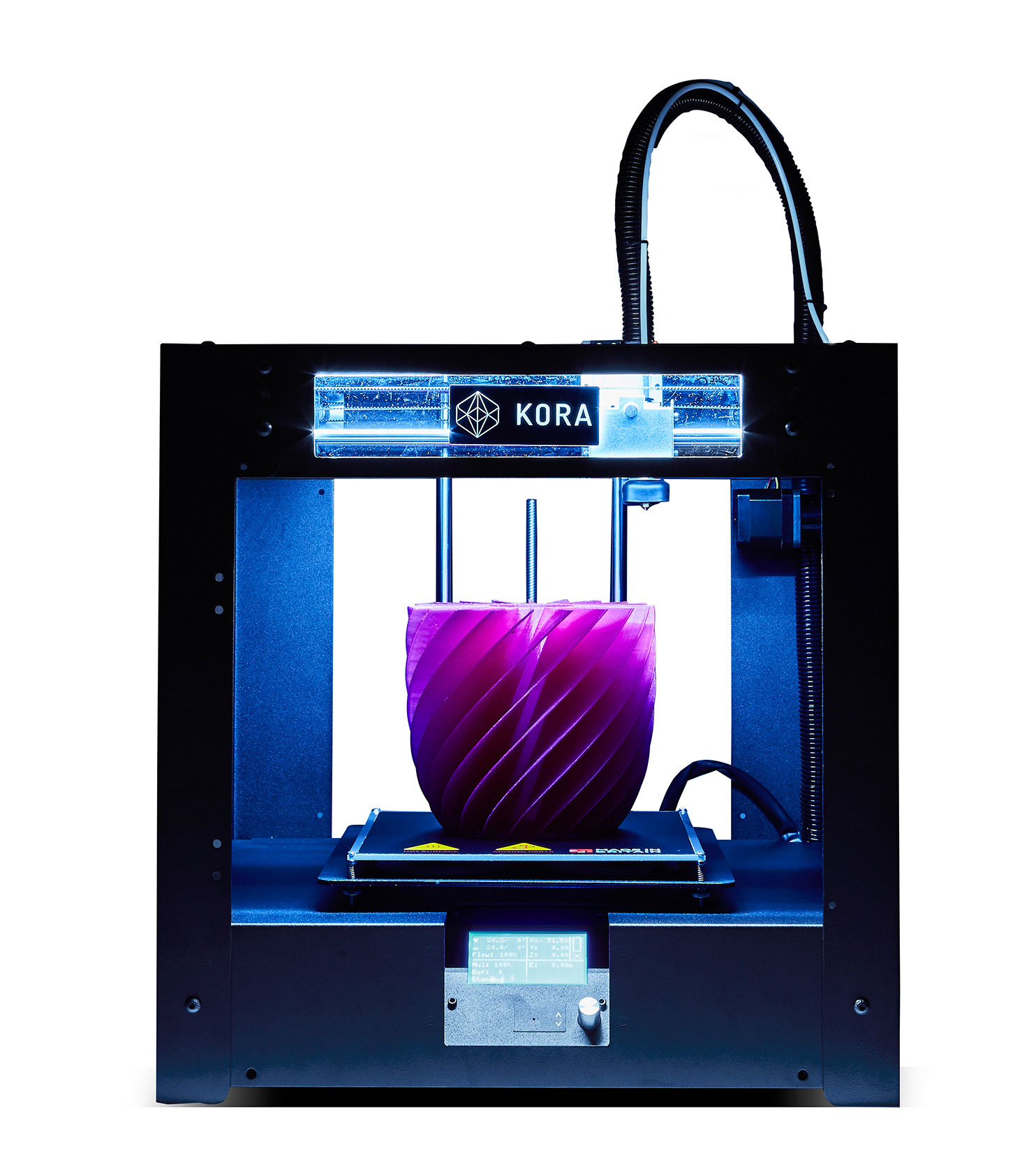

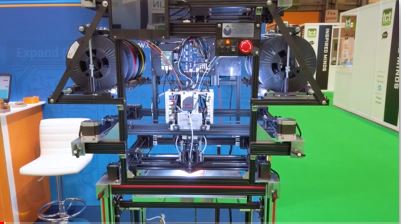

There are various 3D printing technologies. This document is concerned with Fused Filament Fabrication (FFF) which is the most commonly used technology in schools and colleges. FFF printing is a process of laying down melted plastic filament in a series of layers. The adjacent layers cool and bond together before the next layer is deposited (Figure 1).

This document has been developed in collaboration with the HSE and provides guidance to users of this technology on how to work safely and mitigate potential associated risks. These mitigating actions are referred to as control measures. This document is aimed at those who are responsible for purchasing and looking after 3D printing equipment in schools and colleges to ensure that employees and pupils are safe. This advice may also interest a wider audience, including home users of desktop 3D printers.

Why you should take notice of this advice?

The use of this technology is relatively new and published studies have suggested that filament combustion products may present a risk to health when inhaled. Individuals most at risk include those with pre-existing asthma and breathing difficulties and those predisposed to developing asthma. This document identifies areas that should be considered before purchasing and when using 3D printers, and recommends measures that should be put in place to reduce these risks. The term 'recommendation' is used to highlight the need for action(s) to be taken considering the most relevant regulations.