Health and Safety at Work

1 Mar 2019

Cover 3D printers in schools to reduce risk, says new HSE-backed guidance

Robert Preston Health And Safety Magazine

Health, Lung disease, Risk assessment, Safety

An HSE research project has led to new safety guidance for schools and colleges on the safe use of desktop 3D printers, which recommends that the equipment should be used inside an exposure control cabinet to reduce harmful emissions.

Exposure control cabinets should also be retro-fitted to open-frame 3D printers, if other local exhaust ventilation (LEV) systems are not available, according to the new guidance from CLEAPSS, the Consortium of Local Education Authorities for the Provision of Science Services.

G276 3D printing in schools and colleges – Managing the Risks sets out additional control measures, including choosing less hazardous filaments, reducing the printer nozzle temperature and ensuring that the rooms printers are used in are well ventilated.

Issued with HSE endorsement, the guidance warns that standing close to a desktop could trigger respiratory symptoms in some individuals, while there may be longer-term health concerns for those who spend long periods using 3D printers.

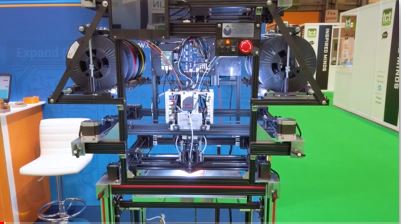

The HSE research project that underpins the guidance focused on smaller 3D printers, of the type commonly used in schools. The research found that the heated filaments emitted large numbers of very small particles and volatile organic chemicals which could be breathed in.

However, more research would be required to establish if, under real use conditions, these printers release sufficient concentrations of emissions to cause harm.

The HSE’s Research Report 1146 Measuring and controlling emissions from polymer filament desktop 3D printers describes laboratory tests on three different models of printer based on the fused filament fabrication (FFF) process, also known as fused deposition modelling (FDM).

In this system, the most commonly used 3D printing technology in schools, the printer heats, and then extrudes, a filament of polymer material.

This produces a strand of molten plastic, which then cools on the print bed to form the object being made.

The three printers each made a test object, using a range of filament materials, including polylactic acid (PLA) and acrylonitrile butadiene styrene (ABS). The tests were repeated with and without an enclosing hood in place.

The study also found that emitted particles were in the size range to potentially enter the airways and lungs, and that emission rates were higher when using ABS than for PLA.

Additional hazardous chemicals, such as styrene and methylene diphenyl di-isocyanate (MDI), were released from some types of polymer filament, but the report says it is not yet clear whether concentrations of these chemicals are sufficient to cause harm if inhaled in real use.

According to the conclusions of the research report, “placing an enclosing hood over the 3D printer reduced particle emissions released to the room by 97%”.

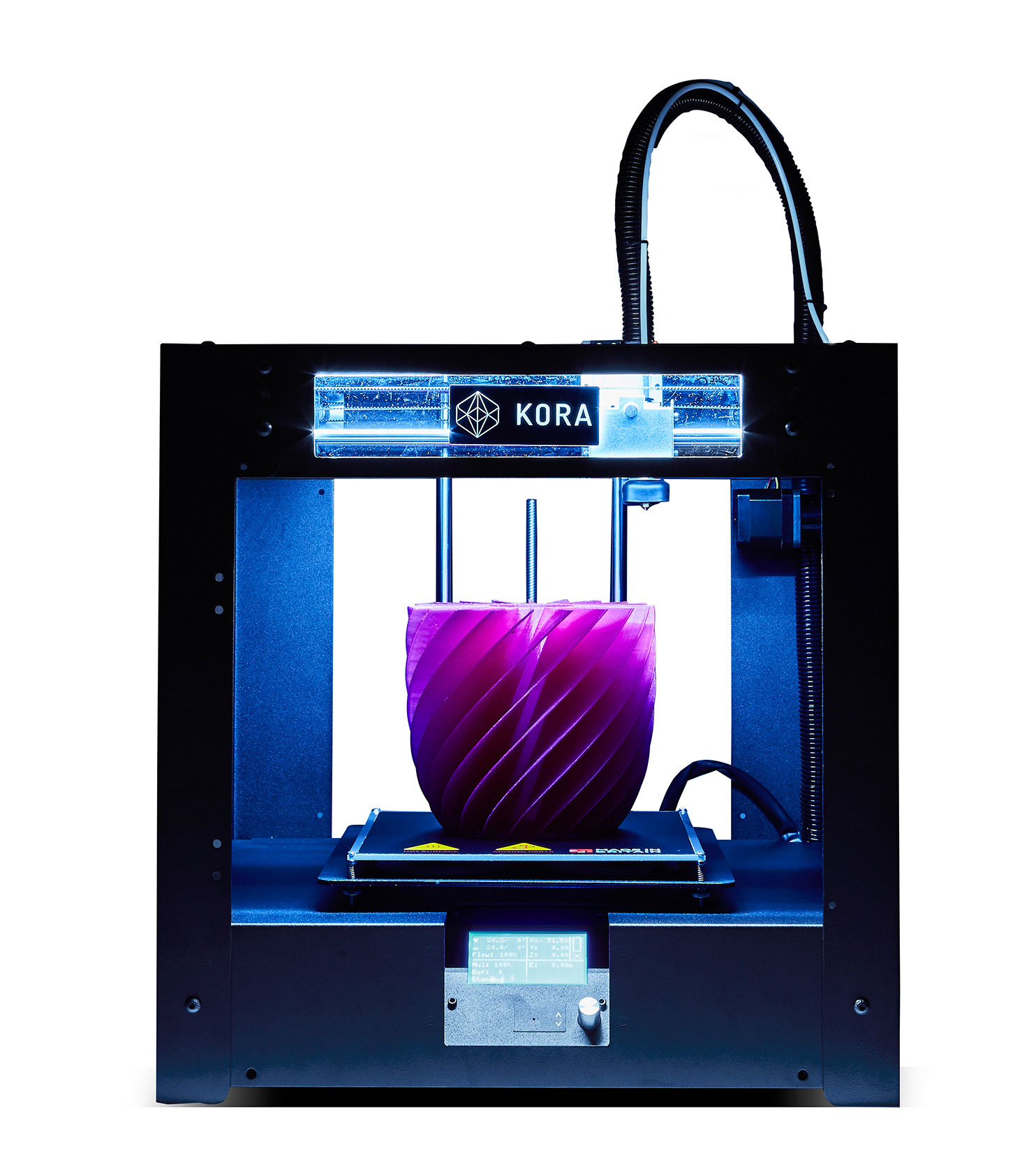

The enclosing hood used in the tests was supplied by 3D printer manufacturer Kora 3D.

It was part of a working group formed by the HSE in September 2015 to discuss concerns about using polymer filament desktop 3D printers in schools.

The working group also included CLEAPSS, the Manufacturing Technology Centre, the British Standards Institution and Peritus Health Management.

Kora 3D voluntarily suspended sales of its own FFF/FDM printers between 2014 and 2018, until the research was complete.

It has now developed a safety cabinet with air filtration for commercial sale, which has been tested and approved by the Health and Safety Laboratory.

Kora 3D managing director Steve Burrows said: “We strongly believed that although FFF/FDM style 3D printing delivers huge benefits, not enough had been done until now to investigate the potential risk to users and bystanders.”

“Our talented team has worked closely with the HSE to develop a product which finally makes FFF/FDM style 3D printing safe.”

Dave Parry, design and technology lead adviser at CLEAPSS, said: “With 3D printing being encouraged as part of the curriculum, teachers and pupils are using 3D printers on a regular basis, so we’re pleased to see the introduction of fully integrated extraction systems that trap potentially harmful fumes and particulates to prevent exposure to users.”