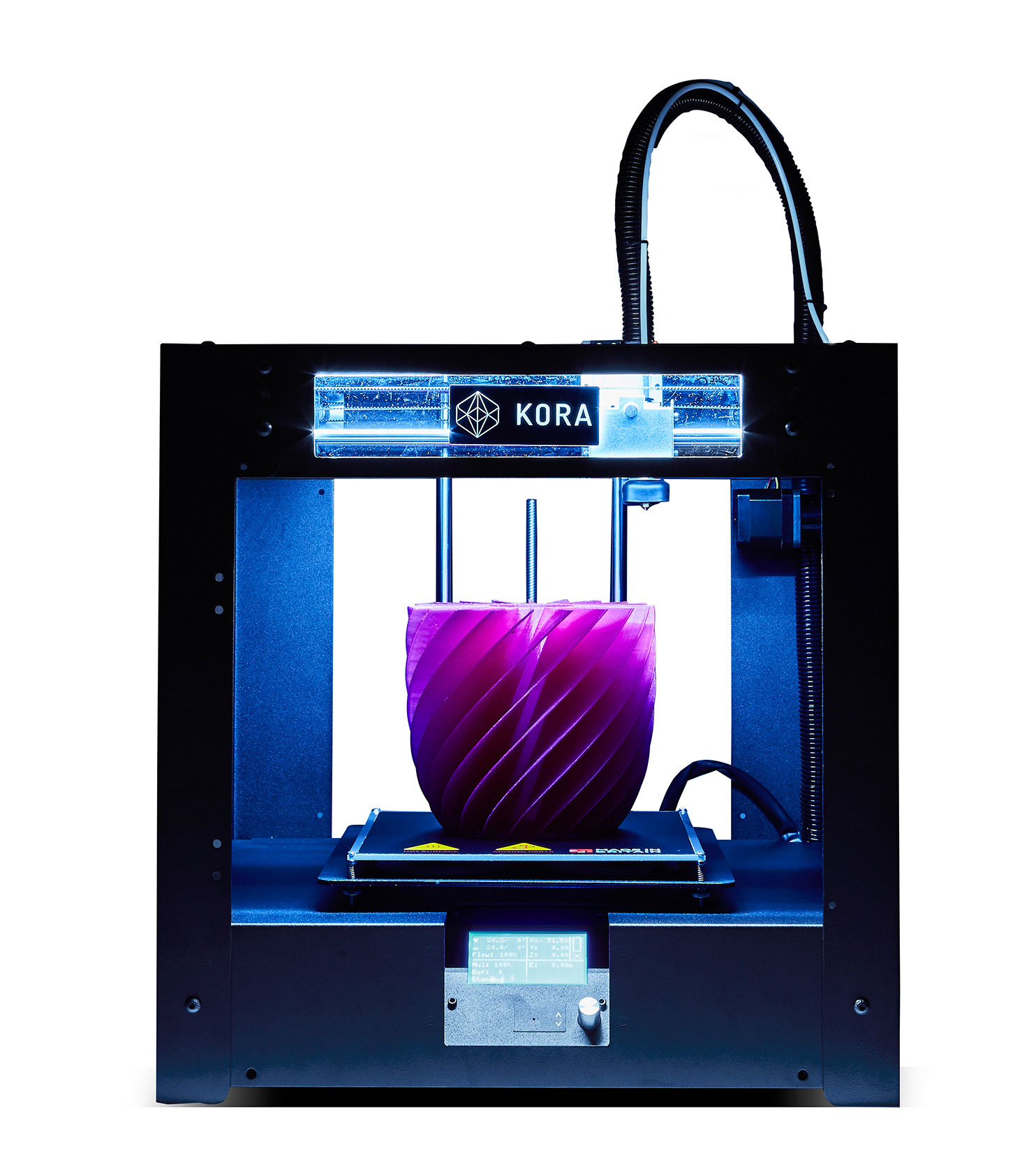

Kora 3D Develops Safety Cabinet to Protect Against FFF Desktop 3D Printer Emissions

28 Feb 2019

The company suspended sales of its extrusion-based desktop machines for four years while the research was carried out.

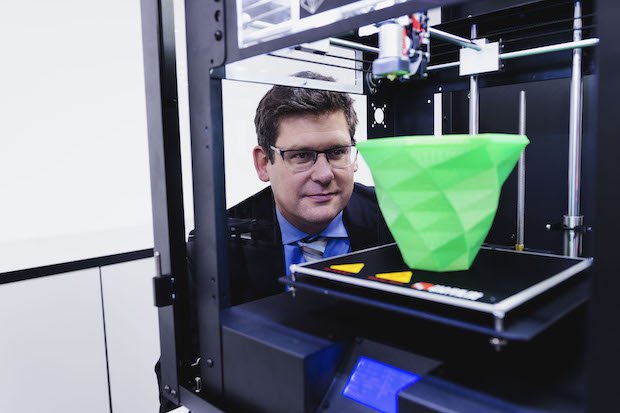

Kora MD Steve Burrows with the SC-01

Kora 3D has developed a safety cabinet to protect the users of extrusion-based 3D printing from potentially harmful emissions transmitted by the machine.

The company had previously suspended sales of its Fused Filament Fabrication (FFF) systems, after entering into a research collaboration with the Health and Safety Executive (HSE) and the British Standards Institute (BSI). This study began in 2015 and worked to identify the risks of extrusion desktop 3D printing systems and develop ‘good practice guides’ to address them.

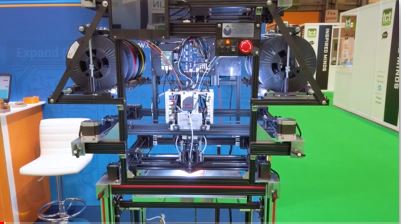

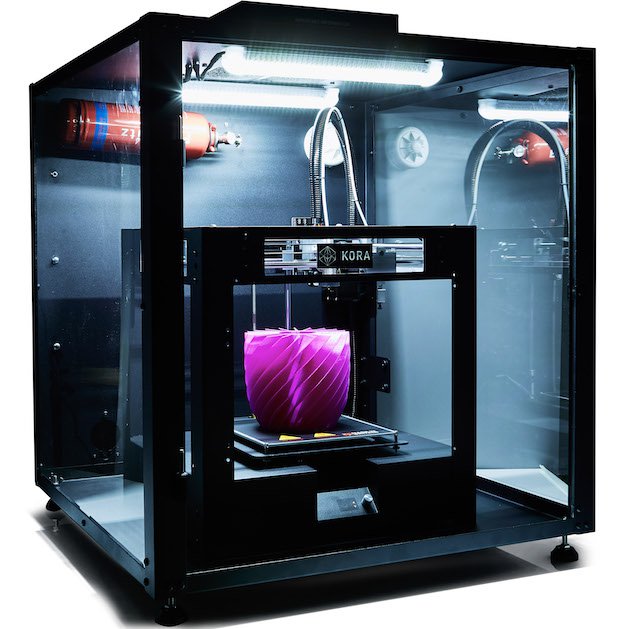

As a result of the research, Kora has harnessed the recommendations given by HSE to develop the Kora SC-01 Safety Cabinet, which fits most ‘standard sized’ FFF desktop machines on the market. The cabinet draws clean air from the surrounding environment through a specialist filter cartridge at the top of the cabinet, and works to remove potentially harmful emissions.

These emissions include particles of a size range that could enter the airways and lungs of operators, and also be released into the general environment because many printers have no form of control of particle capture. The research, detailed in HSE’s ‘Measuring and Controlling Emissions from Desktop 3D Printers’ report, also found some plastic filaments processed on desktop machines release vapours which become hazardous to humans once heated. During testing, it was found by placing the desktop machine inside an enclosed chamber with filtered ventilation, particle emission was reduced by around 97%.

Kora SC01 Safety Cabinet

“It’s clear that FFF/ FDM style 3D printing is a growing sector and one which offers fantastic benefits to business,” commented Steve Burrows, Managing Director, Kora 3D. “However, our four-year study alongside the HSE has confirmed the importance of having a greater understanding of the equipment and the need to pay more attention to safety management. It was a huge commitment and a risky commercial decision to cease sales of our FFF/ FDM style 3D printers. However, we strongly believed that although FFF/ FDM style 3D printing delivers huge benefits, not enough had been done until now to investigate the potential risk to users and bystanders.

“At the heart of Kora 3D is a real passion for problem solving, so our talented team has worked closely with the HSE to develop a product which finally makes FFF/ FDM style 3D printing safe. As the only company currently with an HSE/ HSL (Health & Safety Laboratory) tested product, we believe we are now in a very strong commercial position to ambitiously grow our business.”

The HSE is now hoping organisations using extrusion-based desktop 3D printing will now take reasonable action in accordance with its new guidance. Businesses using FFF desktop systems without adhering to the new guidance could find themselves in contravention of the Provision and Use of Work Equipment Regulations 1998 (PUWER), Control of Substances Hazardous to Health (COSHH) guidelines, and the HSE's Management of Health and Safety at Work' code of practice.

Since the research was carried out, the Consortium of Local Education Authorities for the Provision of Science Services (CLEAPSS) has also issued its own guidelines to try to protect staff and employees using desktop machines in schools. It anticipates other sectors will follow suit.

Kora 3D has resumed sales of its Pro series of desktop 3D printing platforms.