Kora Unveils Recycling Program

4 Jun 2019

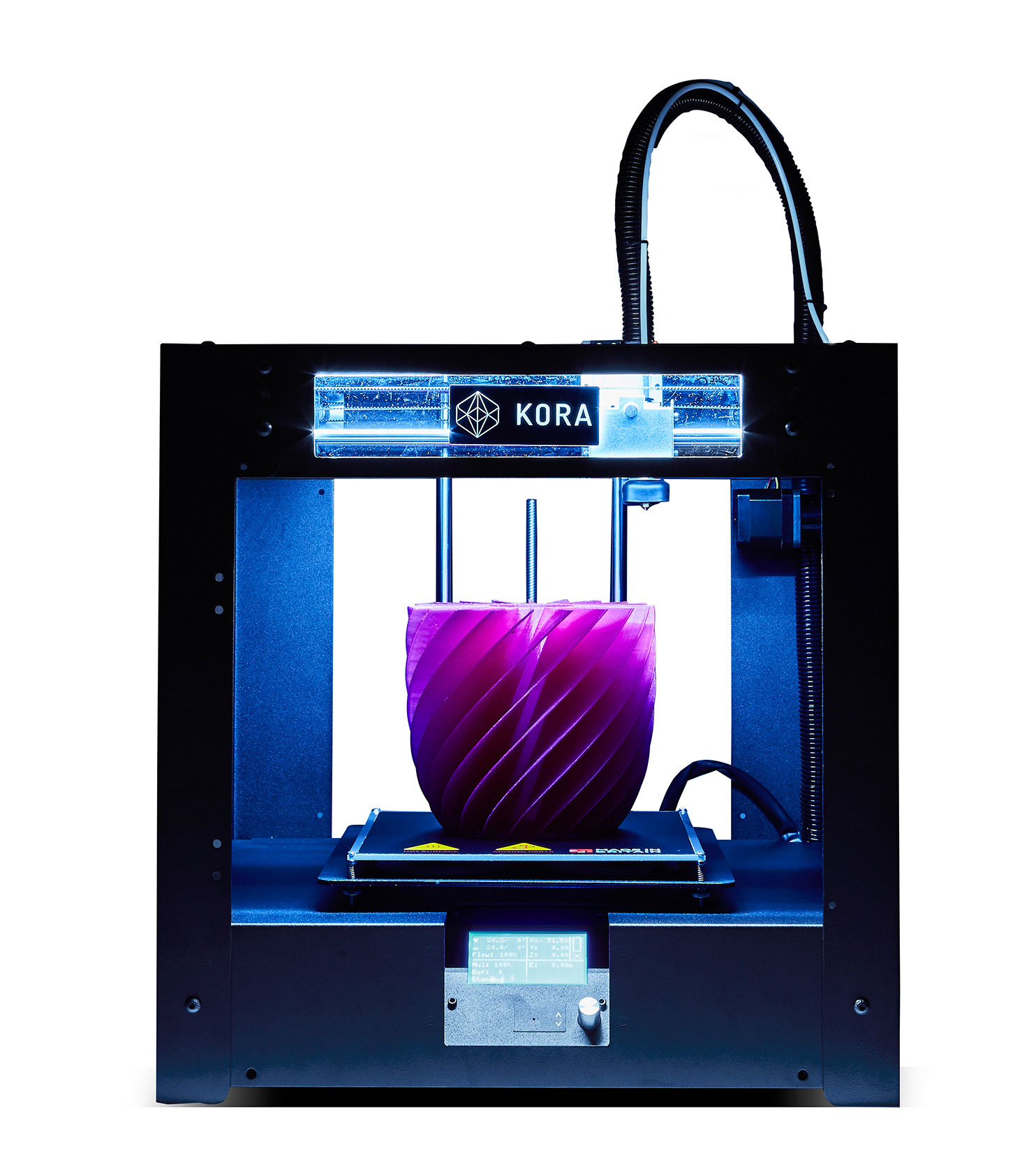

KORA 3D PUTS SAFETY FIRST WITH UNIQUE 3D PRINTING ACCESSORIES

One of the UK’s leading manufacturers of desktop 3D printers, Kora 3D, has expanded its product range with the launch of two first-to-market innovations.

Kora 3D’s unique Formula 3D® bed adhesive is a specially formulated multi-polymer mix which secures the first layer of a 3D print to the 3D printer’s build plate during the printing process and ensures it can be easily removed once the process is complete. It improves 3D print quality by ensuring the models don’t become loose, preventing the bottom layer from warping and reducing model failure and so reducing filament wastage.

A non-flammable, water-based bed adhesive, Formula 3D is one of the safest bed adhesives available and boasts an alcohol content of less than 24%; alcohol-based bed adhesives typically have an alcohol content between 40% and 90%. Formula 3D is also applied to the build plate using a foam head, rather than a spray, reducing the amount of adhesive required per print and avoiding contamination of 3D Printer mechanical parts and bearings. It has an industry-leading shelf life of c. two years.

Developed over three years as an alternative to spray-on adhesives which, due to existing legislation surrounding aerosols, cannot be shipped overseas, Formula 3D is available in 100ml and a 500ml top up bottle and is suitable for use with the majority of build plates and 3D printing filaments. Because it is not an aerosol, Formula 3D can be posted anywhere in the world and can be applied to either heated or unheated build plates. Its unique formula is designed to withstand build plate temperatures in excess of 80°C.

Also launching is the new Safety Cleaner 3D, an eco-friendly anti-static cleaning spray designed specifically for use with both safety cabinets and 3D printers. It prevents static build-up on metal and plastic parts, removes and further repels dust and small particles in and around 3D printers. Residual emissions can be easily removed utilising Kora Safety Cleaner 3D.

As a result, the cleaning spray also addresses part of the Health and Safety Executive’s recently released report Measuring and Controlling Emissions from Desktop 3D Printers.

Both new products are available in refillable bottles, delivering a significant saving in both cost and materials, and reducing the number of single-use plastic bottles being manufactured. Kora 3D are dedicated to reducing plastic waste within the environment. Their “Refill Bottle Programme” offers users a 20% discount when the used bottles are returned by the user to be refilled.

Steve Burrows, Managing Director of Kora 3D, said: “Health and Safety is our top priority so we’re proud to have developed an incredibly effective print bed adhesive that is safer to use than many of the alternatives currently on the market.

“Formula 3D is also more resource efficient because, unlike spray-based adhesives, it is easy to apply accurately, which also reduces the risk of any adhesive coming into contact with the 3D printer’s moving parts which, if left to accumulate, can cause serious 3D Printer damage over time.

“We’re delighted to add more options to our ever-increasing collection of products and firmly believe these new additions will become go-to solutions for users of 3D printers for many years to come.”