The Invisible Threat To Schools

13 Aug 2020

School Guide to Offset the Invisible Threat in Fused Filament 3D Printing

School classrooms are ideally positioned to make the most of 3D printing technology, benefiting students by giving them new learning possibilities and encouraging creativity and innovation. However, it can also pose unintended health risks to its users, except that few scientific studies have been done to evaluate the impact of 3D printers on indoor air quality. So, to understand these potential human health impacts, researchers at the Atlanta-based scientific institute Chemical Insights focused on identifying, measuring, and comparing 3D printer emissions, and found that they give off ultra-small particles and volatile organic compounds (VOCs) while operating. Among other results, the investigation also lists ABS filaments as typically having higher emissions, followed by nylon and then PLA. The discoveries made during the four-year research are now available as a guideline for U.S. schools to identify and assess the toxicity risks of the emissions released during 3D printing.

Research and findings from the toolkit, 3D Printer School Safety: A Guide for Supporting Indoor Air Quality & Human Health, jointly conducted by Chemical Insights, an Underwriters Laboratories institute, along with researchers from Georgia Institute of Technology, explains how 3D printers emit ultrafine particles (UFPs) and VOCs during operation. According to Marilyn Black, vice president and senior technical advisor for Chemical Insights, by the time the project began, they knew that 3D printing was probably giving off a lot of particles into the air, but needed to characterize them, from the type of particles to the sizes and the levels of chemical emitted.

After years of research focusing on fused filament desktop printers, Black and her team found that they generate a complex mixture of airborne particles—many of which are very small in size—as well as some known VOCs, like irritants, carcinogens, and odorants. This means that exposure may present a human health hazard, in particular when a person stands next to a printer in a closed room with minimal ventilation.

“As the 3D printing market began to really hit the consumer and soft industrial spaces, especially schools and libraries, some five years ago, we began getting a number of calls from people who were saying that 3D printers at school were emitting unusual odors and that children were having some sort of respiratory reaction when they were using them,” Black told 3DPrint.com. “We began wondering if there could be something going on that we were not aware of and as we researched it, we found out there had not been a lot of scientific studies to understand what might be coming from these 3D printers while they operated and how they might impact the air quality in these spaces.”

When mitigating risk there is a hierarchy of controls to consider. (Image courtesy of Chemical Insights)

In the initial research, the scientists found that aerosols generated from the 3D printing process were primarily particles, with over 90% of them being ultrafine particles, super small and, unfortunately, very concerning from a health perspective. When inhaled, they can go deep into the pulmonary system, cross into the bloodstream, and even penetrate the organs and the brain. The team also did some first level studies on toxicity and discovered that all of the particles displayed some level of toxicity, but more work is being done to understand why. Black suggested that all the signs indicate that “we need to be concerned” and “minimize exposure.”

Using 3D printers in closed school spaces means they are often poorly ventilated and around children with vulnerable, developing respiratory systems that can result in a risk of toxicity, especially as children breathe more rapidly than adults and so absorb more pollutants. In order to cut down the risk, Chemical Insights has made its 3D printing toolkit available to schools nationwide by including it in the U.S. Department of Education’s (ED) Green Strides online resource portal, a one-stop system providing K-12 schools with tools to pursue knowledge and practices to help make them more environmentally friendly and ecologically responsible. The new informational guide will help administrators, teachers and parents better understand how to safely use 3D printers.

“These are unintentional consequences of the technology that people are simply unaware of, but It can be managed. We need to learn what the issue is and the steps schools can take to minimize the health hazard from respiratory cardiovascular concerns that arise from exposure to toxic particles. One thing we were able to determine is that a person standing next to a 3D printer, is equivalent to being next to a freeway, which are among the most toxic sources of pollution in the world,” Black went on.

The primary concern from these 3D printers is the “cocktail mixture” of the different particles which Black found came across all the printers in the study, as well as all the filaments. The expert described the “soft environments” where desktop 3D printers thrive as not as regulated as industrial counterparts—where the environment is supervised and has to follow specific certifications. This is why she thought it very helpful to create a guideline for the general indoor environment that will help keep children safe.

Some of the recommendations include selecting locations with good room ventilation, operable windows, or local exhaust fans that can be placed above the printers so that users cannot hover over the device to look at the process while operating. Instead, schools should consider implementing tools, like cameras or observation windows, looking into the enclosed rooms for children to watch the process without being exposed to dangerous particles. Chemical Insights also recommended purchasing 3D printers and supplies that have been independently verified or certified to produce lower emissions, and operating printers according to manufacturer’s instructions and safety recommendations, which includes using the printer nozzle at the lowest recommended temperature.

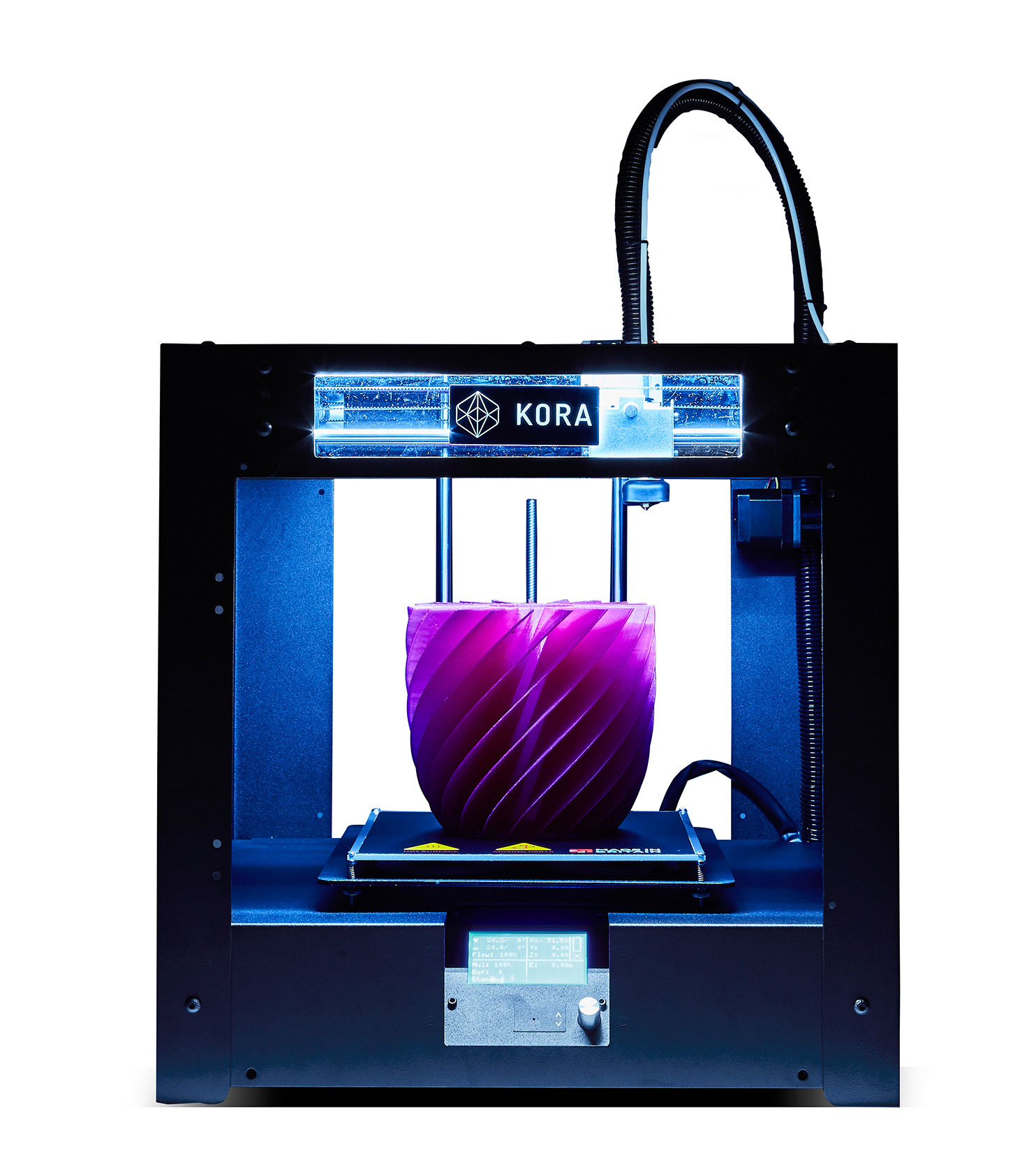

Engaging 3D printer manufacturers in the study was not difficult. Black described how they were eager to participate by supplying their printers to use in the research. It turns out that many of the companies were also getting questions from concerned customers about strange odors and user reactions from 3D printers when operating. Although Black said no brands or products were identified, the team did test a range of different printers with high market shares that they knew were being widely used in schools, as well as commonly used filaments.

“Luckily, the 3D printer manufacturers are listening, they are looking for solutions, building enclosures that may have a filtration system to pull the emissions away. Now we know that trying to control the situation is going to be the best situation,” said Black.

Focusing on emerging technologies to understand whether there might be any unintentional health hazard present is part of Chemical Insights’ mission. Thanks to the development of affordable, compact, and user-friendly 3D printers, consumer use is booming, particularly in classrooms, so knowing what chemicals are in the air during the process can help thousands of people avoid serious health risks that could lead to complications later on in life.